About Arrow Timber Framing

“…designed for beauty and engineered for strength”

The Arrow Timber Team

Bert Sarkkinen

When I was 16, I quit my job as a farm hand and went to work for my father, the owner of Scandia Construction, as a framing apprentice. It was my golden opportunity to learn about the building industry from the skeleton up. For 6 years, I learned all the nuances of real quality framing over other “good-enough” methods. My father’s philosophy was that mistakes, while they should be minimized, can be fixed. And, he taught me how to turn out a fine quality building without taking forever! While training was painful, I kept working on learning logistics, quality control, visualization, roof math, and all the requirements needed to make the subcontractors’ and general contractor’s lives easy.

“The most important lesson – I was responsible for the functionality of the house.” My father taught me always to add an extra stairway riser when possible, because the stairs would be so much more comfortable. I learned to avoiding door swings hitting toilets, checking code clearance for egress, and leaving room for cabinets and refrigerators were of few of the pitfalls avoided. few. calculations for roof valleys, hips, and tons of framing details. The list just never quit. Read more …

“The love for and fascination with building and creating structures started with building forts and carving projects as a youngster.”

Josh Gedenberg

Josh is our top integrator here at ATF, and he keeps everything running smoothly and efficiently. He wears many hats in operations to include accounting, engineering, human resources, and purchasing. He is also responsible for installation, shop fabrication and shop drawings. His high level of quality control and care keeps projects on track and to the required specifications.

Josh uses his skills of perseverance and money management to ensure both clients and employees are well taken care of. We also appreciate his warmth and professionalism. Josh was a top graduate in school and his intelligence and sharp mind are quickly evident when you visit with him. He likes to have all the answers no matter how hard the question. Josh lives the ATF core values and his decision making skills are top-notch. Past work experience included framing custom homes and he spent 15 years in truss sales.

“Growing up in New Hampshire, as a small boy, I always knew I wanted to be a timber framer. After working in construction in NH, I was invited by my employer to move to the Northwest to continue my construction career. My wife, Emily and I love the Northwest. In my free time I enjoy spending time with the kids doing some fun and unusual projects like smelting aluminum cans into ingots for cast aluminum parts. I also enjoy working on my ’64 Chevrolet Bel Air!”

Donna Wirkkala

Getting to know Donna is getting to know the quintessential Finn – reserved, quiet, loyal, smart, competent, and industrious.

Having lived in Finland, I understand and appreciate these traits which Donna exhibits. As an employer, I obviously love it! But just like everything in life, there is no free lunch. When I eventually goof up enough to get on her bad side, I’ll have to work like a dog to straighten things out! That is just how it is with Finns, but it is an easy trade-off to accept! Now just maaaaybe, with the passage of time, I’ve accumulated enough hard-won wisdom to avoid goofing up, but I wouldn’t advise placing any heavy bets on it!

Should you happen by our operations in Kalama, you will likely meet Donna. As our bookkeeper and receptionist, her desk is positioned by the front door. She won’t talk your ear off or entertain you by clowning around but will efficiently help you get whatever you came for. Just. Like. Always.

Thanks, Donna! We all appreciate your steady, reliable service.

I like to spend my time with my family, reading a good book or sitting next to water in the sun.

Oren Matson

Some people can adapt and learn so fast, it sometimes makes me feel like I am standing still!

We all benefit from Oren’s ability to swiftly learn and use technology.This intelligent young man often doubts his own ability, but I have learned how to coax valuable opinions from him. I’ve also come to enjoy his subtle, nuanced expression.

Oren has continued to develop his job here on our team at ATF, and maximize what he can do as a designer. He is efficient and on point!

One place I would like to go is Switzerland and see the Swiss Alps. Germany is another place I would like to see.

Taylor Meckling

Some people can wax expressive and even poetic, while others struggle to communicate. Taylor falls into the first group!

He has an intuitive grasp for nuance and clear descriptions. This skill was very helpful when writing The Art of Hybrid Timber Framing.

As a student who has studied architecture, his vocabulary and planning skills help us optimize floor plan tradeoffs, brainstorm ideas, and create decision compass descriptions for clients.

Taylor is also a key part of our Marketing team, with excellent video editing and enhancement skills.

I really enjoy outdoor activities such as trail running, mountain biking and hiking. I like to read a lot, listen to Podcasts, and generally be well informed.

Greg Somero

It may sound a bit trite to be talking about trust when describing Greg. After all, trust should be a given. If you can’t trust someone, you have no business hiring them, right? But from the moment I got to know Greg, I instinctively could feel deep trustworthiness.

He did not have an immediately transferable skill set when changing industries to join our team. And he still has quite a bit to learn. But he is a solid, no-ego team player. I trust that he is applying himself every day. I trust that he is improving team relationships. I trust that he is steadily learning and acquiring the needed skills. I trust that he will speak up when I get out of line. And I trust that he is working for the long-term good of our clients.

When Josh and I were interviewing Greg, we did not have an immediate need to hire him, but we both knew he lived our core values and was the right guy to “get on the bus.” Nobody working with Greg today feels like we made a bad decision. That includes me. And I should know what a lousy decision looks like. As an incurable optimist, I have made a TON of bad hiring decisions. But not this time! Thanks for the help, Greg! P.S. Don’t let it go to your head!

Growing up in Arizona gave me a real interest in the history of the American West. It’s always been a dream of mine to take a few weeks and explore the ghost towns in the backcountry of Arizona, Utah, and Colorado.

Lucas Holmgren

Lucas has been part of the ATF team for quite

a while. He has experienced some challenging times. I’m tickled pink with how he persevered and maintained his relationship with us.

Without his help and influence, we could not deliver high-quality video content to our YouTube subscribers.

Also, I really enjoy working with Lucas implementing continual improvements to make our website more and more user-friendly. I’ve noticed how the respect, stability, and appreciation between Lucas and the ATF team definitely go both ways.

Keep it up, Lucas!

I enjoy fishing, especially with my kids. They’re fascinated with learning about the species, and I am too. Recording and performing music is essential in my life. Creativity is very fulfilling, which makes my job at Arrow especially enjoyable.

David Carillo

David is a Timber Frame veteran! He has pushed himself to learn as much as he can about Timber Framing, from strong joint design to safer, more efficient methods for the artisans in the shop.

Many of his free-time hours were used to reach his level of excellence. Visualizing triangles, using trigonometry and running the shop on schedule – so our clients wear a wide smile!

David doesn’t like to take center stage. But as the most skilled artisan on our team, he fills the role of foreman. For a background guy, this can be a tough job.

Recently, David is focusing on developing the emotional intelligence required for good leadership. Despite his reluctance, he is committed to bringing his best game to ATF!

I really like to spend a lot of free time with my children. I also enjoy volleyball and soccer. I I enjoy reading if there are no distractions.

Raul Lopez

Some people are so reliable it hurts. Raul is one of them. You know the type.

If their vehicle is missing 10 minutes before starting time, you start to wonder if your watch is broken!

Raul always has a proactive, helpful attitude. No matter how frustrating things get, Raul always looks for some positive thing to do. These traits of Raul’s can be easy to take for granted! But he knows we all appreciate the steady momentum he gives our team.

And his timber crafting proficiency has followed the same trajectory: always improving, always pushing forward. Raul helps us to consistently deliver excellence.

I have always been attracted to wood. As a nine-year-old I started helping my father cut cedar and pine. I also had to commute by bike two hours every day. And it took me 6 years to finally get hired at ATF!

Jacob Jenkins

The desire to learn stuff is a universal driver. I have noticed and heard how Jacob really gets satisfaction from this.

Recently, I worked with Jacob and another artisan on a timber frame install. As an apprentice who had spent most of his time crafting in the shop, Jacob was mentally playing catch-up the whole day. There is a lot of construction choreography involving details, steps, and logistics while working in the field.

Sometimes communication gets a little “terse” with a lagging dance partner. (Often a learning apprentice) At some point I let Jake know his efforts were appreciated and not to feel like a failure. Jacob understood completely. “I get it.” He said. “But I really like working in the field, because I’m learning a lot!” Great answer Jake! You are living one of our core values: To learn and do.

I like to spend a lot of my free time in the gym working out, rock climbing, or doing jujitsu. If I’m not doing those three big items, you might find me hiking, swimming, or fishing.

Nolan Matson

As a young member of our sawyer team, Nolan is steady and dependable.

Why is it so gratifying to see young workers apply themselves? Do we see our younger selves in them?

At Arrow Timber Framing, giving others opportunity gives us a sense of purpose. It also aligns with our core values: help first, and work for the long-term good.

This warm, fuzzy apprentice/mentor relationship can sour if ingratitude or a poor attitude gets a foothold. But with this bright, energetic young man, it has been nothing but fun.

I like to go dirt biking, hiking, and camping. I like to spend most of my time outside when the weather’s nice. I enjoy dirt biking in the summer and being indoors in the Winter

Burt Matson

“As long as I’m not going under, I’m moving forward.” Burt’s response to question number four is very revealing. It reveals profound wisdom, peace of mind, and self-control.

These characteristics enrich us as a company, striving to provide deep value to both our clients and employees. The ability to live within one’s means and delay gratification strengthen and help stabilize us as a team. In addition, Burt has past experience in framing, concrete, foundation, decks, and more! He is a versatile team member.

His wide range of expertise means he can think in a full circle to help us optimize our sawmill operation. This will keep us providing the best, most comprehensive, competitive, high value service to our clients

“I like to hang out at churches. I would also like to visit Prince Wales Island. And it is always fun to hunt new spots surrounded by Doug Fir trees.”

Charlie Wakeman

Location, location, location. That is how we were lucky enough to snag Charlie Wakeman, our mechanic. He lives near our Kalama shop and was driving clear over to Portland for work until he responded to the NOW HIRING sign, visible from I-5.

The cultural fit has been awesome! I love it when I hear the shop guys say, “Give it to Charlie. He can probably repair it.” With his go-to attitude and work ethic, Charlie has gained the confidence and respect of the whole ATF team. Nor is Charlie a wetbehind-the-ears spring chicken!

More than the many practical skills he has acquired in his life, I appreciate his seasoned, straightforward views on life and work. And I think the younger apprentices benefit from his example as well. It has been working out well. I must say the back-scratching has been mutual. Charlie has added woodworking to the collection of hobbies he enjoys! There is a lot to admire about how he rolls. Thank you, Charlie!

About Arrow Timber

Arrow Timber Framing began as a specialized contractor framing complicated, high-end homes. Transitioning from traditional construction to timber framing was a natural progression for Owner, Bert Sarkkinen; he enjoys the challenges of complicated math and angles, crafting modifications to improve the functionality and beauty of a home. While Bert dedicated many hours to design and studying design and learned about joinery, he fell in love with the beauty and lore of the old world craftsmanship. Bert applies the highest degree of quality control and responsibility-oriented training and has a keen eye for balance and functionality. This translates into impeccable timber design and development.

In the ten years it took to mature the business, it was the love of the craft and his passion that was his anchor. His dog-on-a-bone perseverance and the challenges he faced in entrepreneurship laid the foundation for growth and success. While he may be a true optimist, he sets realistic expectations for people and projects. His expertise is demonstrated in his ability to acquire and train the right talent. Retaining apprentices who are our future timber framing specialists is a priority of ATF. In addition, the company has invested into tools and equipment to expedite the design and build process, purchasing trucks and trailers, and building a shop for our operations.

Our customers are a testament to our success. We hope you will help us write future chapters! We would love to earn your trust and take you on an amazing and memorable journey to create your dream building. If you can visualize it, we can make it! The designs are limitless.

Learn Our 5 Core Values

Arrow Timber Framing is a timber frame design and build company. We produce custom timbers that are erected and assembled in new construction homes and commercial buildings all over the US. Arrow refers to this craft and trade as Hybrid Timber Framing. Our team works with homeowners, builders and architects to develop custom timber plans designed for beauty and engineered for strength.

Timbers can be designed to enhance existing dwellings or developed with a new home or building plan in mind. Timbers are crafted to accentuate the beauty of a home or building. Timbers designs vary depending on the intended style of the house or building. ATF is experienced in crafting custom design solutions for any new home or building style. Arrow’s owner, Bert Sarkkinen is an expert in hybrid timber framing and believes his approach to using timbers offers the highest value for owner satisfaction, aesthetics, strength and resale value. Learn more about Bert and his team here.

The Arrow Timber Frame Difference

Arrow uses Douglas Fir Wood for all of our custom timbers, the premiere timber framing wood of timber framers all over the world. Arrow is situated in the Pacific NW, where Douglas Firs grow so there’s no waiting for timbers to be shipped to our location to be milled. All timbers are milled on location at the Arrow Timber Framing Sawmill and are milled to custom specifications. This results in lower timber costs and faster delivery of timber packages to job sites.

Arrow has spent years refining our joinery methods for the installation of green timbers which are designed to allow the timbers to shrink together after installation, instead of shrinking apart. This is a preferred method to kiln dried or RFKD (radio frequency kiln dried) – methods that lead to shrinkage and cracking after installation. Most timber framers in the US use Hundegger CNC turning machines for their joinery methods which limits the kinds of joinery you can use on your timbers, resulting in fewer design options. ATF methods do not have this limitation.

We cut our own timbers with FOHC (free of heart center) methods to prevent checking (cracking.) Commercially made timbers are typically significantly smaller, milled with ‘boxed heart’ methods which lead to cracks on the face of the timber and a giant check right to the heart. Arrow eliminates 80% of the checking by utilizing FOHC milling. Arrow is also able to mill timbers over 26’, which is where most commercial sawmills stop. We mill the largest timbers available, up to 50” wide. The Arrow Sawmill can cut timbers of nearly any size.

Douglas Fir Wood is a national treasure and one of the longest-lasting woods available for hybrid timber framing. Incorporating Douglas Fir into your timber design project will incorporate this rich wood material as a permanent fixture to your home or building.

Mission and Vision

- To help homeowners get exactly what they want, even if they can’t define what that is.

- To prevent homeowners from getting “ugly” timbers and what Owner Bert Sarkkinen calls the ‘98lb weakling’ – weak looking and unattractively assembled timbers; to prevent spending money on poor design and timber results which can erode the value of the home and leave owners dissatisfied.

- To inform and educate buyers on how timbers are used to maximize their design, aesthetic and structural value.

- To demonstrate how Arrow creates the most attractive timber designs and highest value timber packages available in the market today.

“We are the sworn enemies of ugly, and purveyors of happiness.” – Bert Sarkkinen

Competitive Advantages

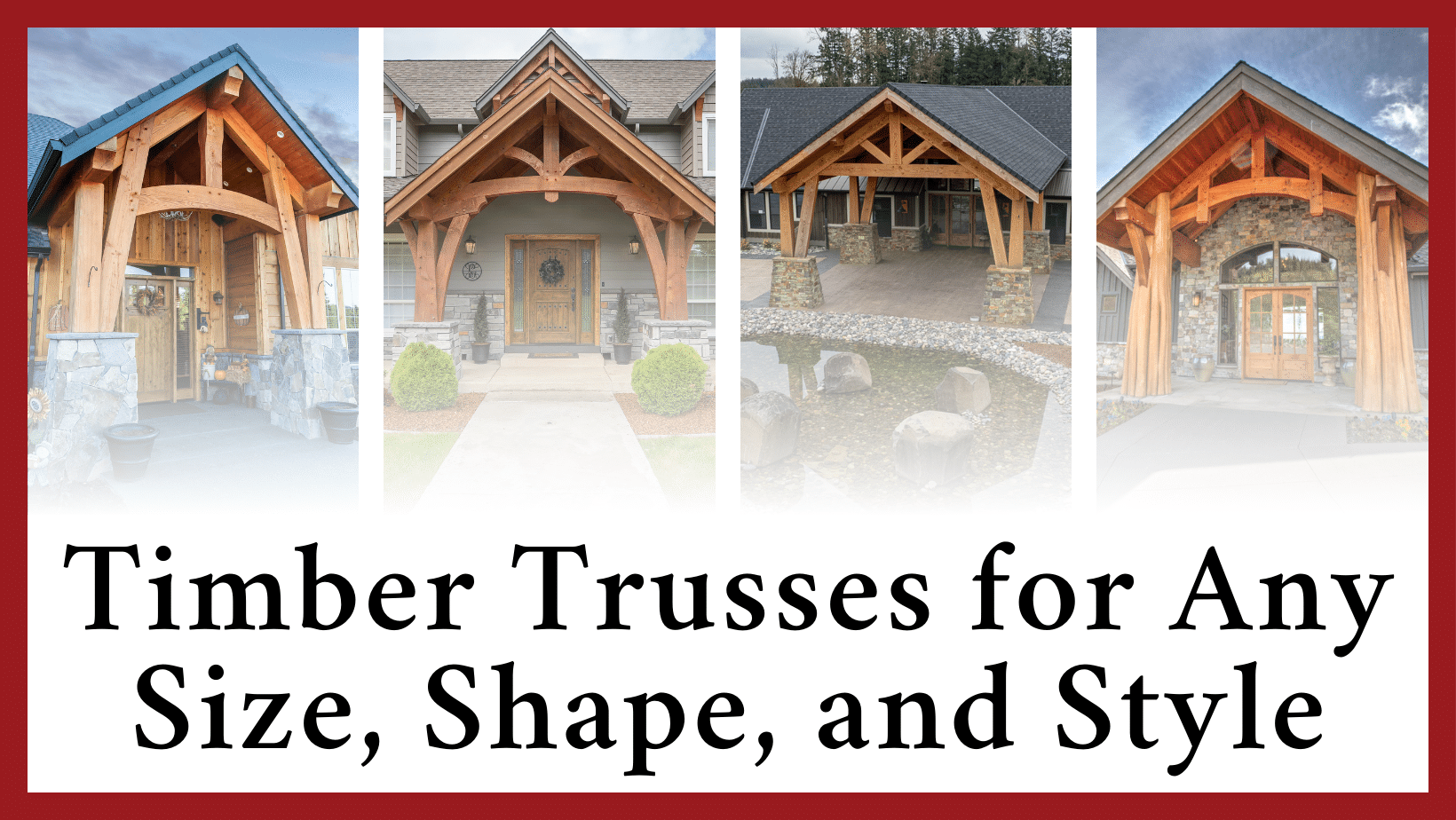

Bert has devoted a lifetime to education on hybrid timber design methods and designs, and how timbers are used to maximize aesthetic value and lasting customer satisfaction. This includes a volume of data rich with images in his book The Art of Hybrid Timber Framing by Bert Sarkkinen, and many videos explaining the timber process. Bert remains hands-on at job-sites, and with clients when needed too. He offers a solid variety of timber design plans based on successful projects that can be customized to each and every customer. Arrow offers timber design and manufacturing for assembly on site – this results in exceptional quality control.

The manufacturing process and methods of joinery are the best in the business, and is based on strength, cost-efficiency and beauty. Many competitors purchase their timbers from other companies and use inferior wood products and joinery methods.

ATF uses a consultative approach which will bring to light hidden project challenges and opportunities for improved beauty. There are two parts to this approach when customers meet with us for a FREE 30-90 minute brainstorming session:

1. The Arrow Team will evaluate the project to determine if it’s a good fit for the customer.

2. Customers receive a one-on-one consultation that begins by understanding where you are in your timber journey – ideation, likes and dislikes, specific timber styles, review of house plans, opportunities and challenges, project timelines, budget and more.

One big advantage for our customers – we don’t have to wait for logs to be milled like other companies, which prevents delays or cost hikes.

What’s different about Arrow’s Design Plans?

We don’t just create blueprints, we create 3-D renderings because most people cannot conceptualize what their house will look like from a flat design. When homeowners see a 3-D model from a blueprint, they are often surprised at what their house looks like.

When designs are drawn and there are bends in the house plan, it will never appear as the house will actually look because the rendering shows the design straight on. So most surprises are related to what the house actually looks like with the bends. Most of the time, it becomes a matter of evaluating, seeing around corners, addressing the problems and areas of opportunity. Problem areas usually need timbers and other design elements.

Featured Project

Here is an example of how Arrow’s expertise, equipment and methods created long-term success for the Port of Portland, including saving the Port and the Portland Airport over $20,000 in project costs.

The remodel of a store at the Portland Airport called for one of the largest timbers to be installed within the Airport. This was the largest of timbers Arrow has ever milled – 18” x 20”x 25’ with the log weighing 26,000 pounds.

The timbers installed from the previous project had significant checking, and you could actually sink your knuckles into the crack. This was because the engineers required kiln drying in their specifications. Arrow advised the the use of FOHC timbers rather than the boxed heart wood method previously used. This time the wood was milled and allowed to dry in place after installation, which is Arrow’s standard method.

House Plans

Arrow never builds the same house twice and no two clients are alike. The possibilities of Timbers and how they are used are endless! Every plan is different, and once you come to ATF and references a plan, we will help you identify in greater detail your individual needs and project goals.

What Areas Does Arrow Serve?

Whether you’re from the land of Douglas Firs in the Northwest, or on the South Eastern Coast of the USA, you can get an Arrow Timber package. Anyone in the United States is welcome to start a brainstorm and build their ideal custom design.

“Thank you, Arrow Timber Framing, for your expertise, professionalism, as well as your creative guidance.

It is our privilege to recommend Bert Sarkkinen, the owner of Arrow Timber Framing, and his crew with deeply felt gratitude and highest regard. Bert’s artistry infuses our home with “heart and soul”.

Barbara and Stuart Morgan

“Bert and his Team have completed phase one on our home that is currently under construction. We couldn’t be happier with our decision to go with Arrow Timber. Bert has been so helpful in the design work and so inspiring to us.

It’s like he can see what I have visualized. His crew has great expertise and craftsmanship as they build the most beautiful timbers. They have done what was needed to complete the project, plus more. As funds allow we will move forward with the construction of phase 2 and will definitely be working with Arrow Timber.”.

Sarah & Karl Rose

Hybrid Timber Framing & The Myth of Full Timber Framing

Hybrid timber framing is the art and craft of incorporating posts and beams into your building projects. It represents the most flexible design system that will accommodate virtually every architectural floor plan, layout or roof design. Love timber framing but not sure about a full timber frame home? With hybrid techniques don't have to use timbers everywhere in your square footage.

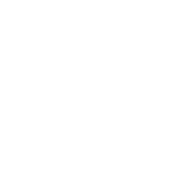

You can create unique artistic beauty with structural strength and eliminate the financial burden associated with full timber framing. Arrow Timber Frame offers 13 truss styles and 7 design styles for custom post and beam construction. Design is only limited by your imagination!

If you are thinking about traditional full timber framing with 100% exposed posts and beams, we recommend reading The Myths of Full Timber Framing.

Most of our clients who initially thought they wanted traditional full timber frame construction learned of the constraints and costs, and made the sensible and sustainable decisions to incorporate Hybrid post and beam construction into their dwellings.

Read Why Hybrid?